In conclusion:

1. Due to the limitation of the composite plate base layer, the composite plate cannot be solid-solution treated. After the equipment is manufactured by the pre-sensitization process before normalizing, the austenitic stainless steel has an anti-intergranular corrosion ability to meet the requirements.

2. The mechanical properties of austenitic stainless steel in the composite plate equipment manufactured by the pre-sensitization process before normalizing meet the requirements.

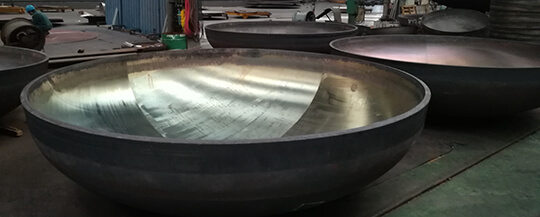

The austenitic stainless steel clad plate is pre-sensitized at 620~650℃, and then normalized at 900~930℃, which enhances the ability of the austenitic stainless steel to withstand the sensitization temperature and improves the resistance to intergranular corrosion. The hot forming of composite board materials provides a reference process.